Commodity Plastics Market to Reach US$ 536.21 Billion by 2030 at 3.5% CAGR

Commodity Plastics Market: Growth Outlook, Segmentation, and Strategic Trends (2024–2030)

Market Overview

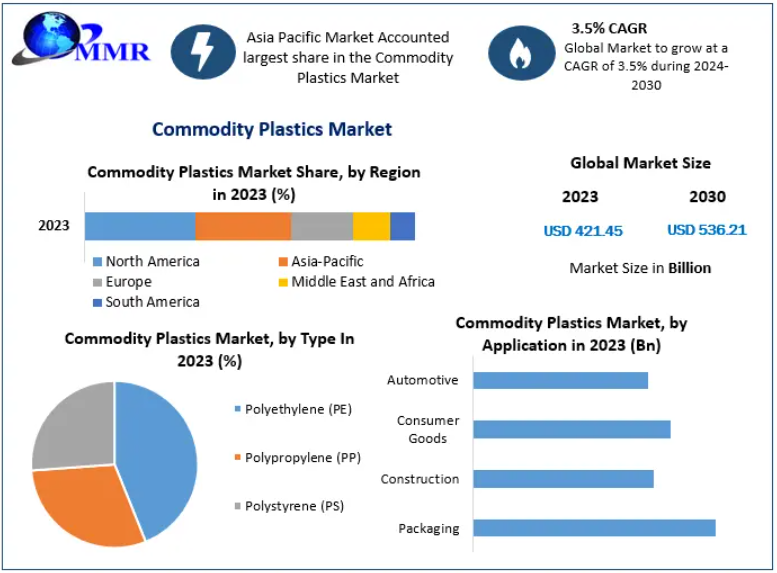

The global Commodity Plastics Market continues to represent the backbone of the modern plastics industry, supplying essential materials used across packaging, construction, consumer goods, automotive, electronics, textiles, and healthcare. Valued at US$ 421.45 billion in 2023, the market is projected to reach US$ 536.21 billion by 2030, expanding at a compound annual growth rate (CAGR) of 3.5% during the forecast period.

Commodity plastics are characterized by their high-volume production, cost efficiency, ease of processing, and wide applicability. These materials form the foundation of everyday products ranging from food containers and household items to automotive interiors and building materials. The steady growth trajectory reflects rising consumption in emerging economies, expansion of packaging industries, and sustained demand from construction and manufacturing sectors.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/2201/

Market Dynamics

Growth Drivers

Rising Packaging Demand

The packaging sector remains the largest consumer of commodity plastics. Rapid urbanization, growing middle-class populations, and changing lifestyles have accelerated demand for packaged food, beverages, and consumer products. Lightweight, durable, and cost-effective plastics such as polyethylene and polypropylene dominate this segment.

Economic Expansion in Emerging Markets

Asia Pacific economies continue to experience strong industrialization and infrastructure development. Low production costs, availability of raw materials, and large domestic markets are encouraging investments in polymer manufacturing capacities across China, India, Southeast Asia, and South Korea.

Versatility Across Industries

Commodity plastics are extensively used in electronics housings, automotive interiors, medical disposables, textiles, and construction materials. Their adaptability, moldability, and resistance to moisture and chemicals support widespread adoption.

Fast and Scalable Manufacturing

Short processing cycles and high production efficiency make commodity plastics suitable for mass manufacturing, reinforcing their dominance in disposable and high-turnover product categories.

Segment Analysis

By Type

The market is segmented into polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polymethyl methacrylate (PMMA), and others.

- Polyethylene (PE) remains the largest contributor due to its extensive use in films, bags, bottles, and flexible packaging. Its chemical resistance, low density, and ease of processing sustain strong demand.

- Polypropylene (PP) finds widespread use in automotive components, packaging, textiles, and consumer goods due to its rigidity and heat resistance.

- Polyvinyl Chloride (PVC) dominates construction applications such as pipes, profiles, cables, and flooring owing to durability and corrosion resistance.

- Polystyrene (PS) continues to serve packaging and insulation markets, although environmental concerns are reshaping its growth patterns.

- PMMA supports applications requiring transparency and optical clarity, including displays and specialty packaging.

By Application

- Packaging leads the market, driven by food, beverage, pharmaceutical, and consumer product packaging demand. This segment is expected to maintain the highest growth rate.

- Construction relies heavily on PVC and PE for piping, insulation, panels, and profiles, supported by infrastructure expansion worldwide.

- Consumer Goods represent a major consumption base for household items, appliances, and disposable products.

- Automotive and Electronics continue to increase polymer usage as manufacturers focus on lightweighting and cost efficiency.

- Medical and Pharmaceutical applications depend on plastics for syringes, packaging, disposables, and laboratory equipment.

Regional Insights

Asia Pacific

Asia Pacific stands as the largest and fastest-growing regional market. Strong manufacturing bases in China, India, Japan, and South Korea, combined with rising domestic consumption and infrastructure spending, drive sustained demand. The region benefits from competitive production costs, expanding petrochemical capacity, and robust downstream industries in packaging and construction.

North America

North America remains a mature but stable market supported by packaging innovation, automotive lightweighting, and technological advancement in polymer processing. Recycling initiatives and sustainability regulations are increasingly influencing material selection.

Europe

Europe is characterized by strong regulatory frameworks and sustainability-driven innovation. While demand remains steady, the region is witnessing increasing adoption of recyclable and circular polymer solutions.

Middle East & Africa and South America

These regions are emerging as important production and consumption hubs due to growing petrochemical investments, infrastructure projects, and expanding consumer markets.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/2201/

Competitive Landscape

The commodity plastics market is highly competitive and consolidated, with global petrochemical leaders dominating production capacities. Key players focus on capacity expansion, feedstock integration, sustainability initiatives, and strategic partnerships.

Leading companies include:

- Dow Chemical

- Exxon Mobil

- SABIC

- BASF

- Sinopec

- LG Chem

- LyondellBasell

- Ineos

- Formosa Plastics

- Reliance Industries

- Braskem

Major strategies shaping competition include:

- Expansion of polymer manufacturing plants in Asia and the Middle East

- Investment in advanced recycling and circular economy technologies

- Development of bio-based and low-carbon polymer grades

- Vertical integration across refining, monomer, and polymer production

Market Trends

- Shift Toward Sustainable Plastics: Increasing regulatory pressure and consumer awareness are accelerating investments in recyclable, biodegradable, and low-carbon polymers.

- Lightweight Packaging Innovation: Brand owners are reducing material usage while maintaining performance, supporting demand for advanced PE and PP grades.

- Infrastructure-Driven PVC Demand: Urban development and water management projects are sustaining long-term PVC consumption.

- Circular Economy Integration: Mechanical and chemical recycling capacities are expanding to close the loop in plastic value chains.

Future Outlook

The Commodity Plastics Market is set to maintain steady growth through 2030, supported by strong demand from packaging, construction, and consumer goods sectors. While environmental concerns and regulatory pressures pose challenges, technological innovation and recycling investments are reshaping the industry toward more sustainable models.

With expanding urban populations, industrial development, and evolving packaging needs, commodity plastics will remain a critical material class underpinning global manufacturing and infrastructure in the years ahead.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness